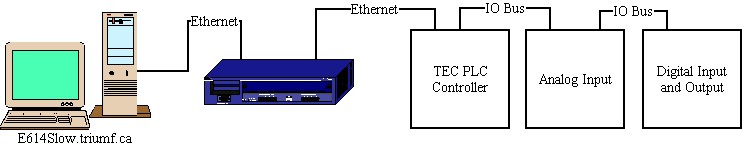

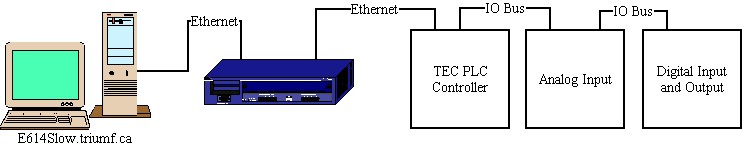

Block Diagram

The TWIST Tec Gas Handling system is composed of a Modicon Momentum Programmable Logic Controller (PLC) with analog and digital input/output boards and a variety of gas components for the target environment. A Ladder Logic program located in the PLC controls the target environment autonomously. The Midas interface is intended for control and monitoring of the devices in the TEC system; all interlocking and complex control is handled by the PLC. The interface between the PLC and Midas is via TCP/IP sockets.

Block Diagram

The PLC program is modelled after the standard ISAC PLC program design, which provides an interface to the EPICS control system by using a set of 16 bit registers in the PLC as a command and status space. The TecPlc class driver accesses these registers, decomposes status bits and places them in the Equipment/Device/Variables area in the ODB. Control of devices is done by setting parameters in the Equipment/Device/Settings area of the ODB which sends commands to the PLC to control devices.

All controllable devices use a generic command word format. The first eight bits have predefined actions, and the remaining ones can be assigned device specific actions. Some bits are pulsed and some are latched.

|

|

The communication channel used by the PLC is TCP/IP using port 502. The set of internal rgisters in the Momentum PLC are located in what is called the 4x space; a 16 bit register space used for integer values in the ladder logic diagrams. In the ladder logic, all accesses to this space is done with register numbers such as 40003 but since this is the only area that the Midas system can access, the 4xx prefix is dropped, and only the offset number from the start of the register space is used in setting up the interface. This is consistent with the EPICS interface.

The TCP/IP interface to the Momentum PLC requires an active connection at all times. The PLC will close all connections that are idle for more than 10 seconds. A KeepAlive function must be provided by the Midas class driver to maintain an open port. In the case of the read port, this is not a problem since the class driver typically accesses the PLC at a fast rate. For the write port, this can be a problem, since there can be long periods of time between commands. The KeepAlive activity is implemented by writing back the PLC Watchdog value read by the Midas class driver to the KeepAlive register. This is done each time the Watchdog value is read to maintain the TCP/IP port.

The Modicon driver is implemented using a shared memory interface between the client application (Midas) and the TCP/IP communication library. Three separate threads are spawned when the driver is started; a read thread, a write thread and a watchdog thread. These threads access the shared memory pool, updating the pool to match the status registers in the PLC, transmitting any commands placed in the memory to the PLC, and monitoring the watchdog counter and updating the keepalive counter. The client application registers with the driver so that it can read and write data in the shared memory. All byte shuffling and bit ordering between the client system and the PLC via TCP/IP is handled by the driver.

All information regarding the PLC registers used by the Modicon driver must be configured in the ODB before the driver is started. A standard Midas ODB ASCII file can be loaded into the ODB to define these values.

There are four different groups of registers defined for the communication channel. These groups are all arrays of eight values.

/Equipment/"EquipmentName"/Settings/Devices/"EquipmentName" where "EquipmentName" is the name of the equipment defined in frontend.c. The ODB structure is defined as:

Key name Type #Val Size Last Opn Mode Value

---------------------------------------------------------------------------

Name STRING 1 32 4h 0 RWD pptplc

IP STRING 1 32 4h 0 RWD 142.90.xxx.xxx

Memory INT 1 4 4h 0 RWD 1100

ReadGroupStart INT 8 4 4h 0 RWD

[0] 289

[1] 33

[2] 749

[3] 17

[4] 1001

[5] 0

[6] 0

[7] 0

ReadGroupSize INT 8 4 4h 0 RWD

[0] 8

[1] 6

[2] 1

[3] 4

[4] 4

[5] 0

[6] 0

[7] 0

ReadOnceStart INT 8 4 4h 0 RWD

[0] 193

[1] 225

[2] 0

[3] 0

[4] 0

[5] 0

[6] 0

[7] 0

ReadOnceSize INT 8 4 4h 0 RWD

[0] 8

[1] 4

[2] 0

[3] 0

[4] 0

[5] 0

[6] 0

[7] 0

WriteGroupStart INT 8 4 4h 0 RWD

[0] 193

[1] 225

[2] 755

[3] 0

[4] 0

[5] 0

[6] 0

[7] 0

WriteGroupSize INT 8 4 4h 0 RWD

[0] 8

[1] 4

[2] 1

[3] 0

[4] 0

[5] 0

[6] 0

[7] 0

Watchdog INT 1 4 4h 0 RWD 749

Keepalive INT 1 4 4h 0 RWD 755

On startup, the TecPlc class driver must initialize the connection to the dd_modtcp device driver. This is done by calling the modtcp_init function and passing it the root key for /Equipment/"EquipmentName"/Settings/Devices/"EquipmentName". The device driver will then extract the parameters from the ODB and run the following functions to configure the modtcp device driver and start the three scanning threads for the shared memory.

modtcpDrvCreate(NameKeyValue, 502, IPKeyValue, MemoryKeyValue); modtcpDrvReadGroup(NameKeyValue, ReadOnceStart[0..7]Value, ReadOnceSize[0..7]Value, ReadOnceStart[0..7]Value, 1); modtcpDrvReadGroup(NameKeyValue, ReadGroupStart[0..7]Value, ReadGroupSize[0..7]Value, ReadGroupStart[0..7]Value, 0); modtcpDrvWriteGroup(NameKeyValue, WriteGroupStart[0..7]Value, WriteGroupSize[0..7]Value, WriteGroupStart[0..7]Value); modtcpWatchdog(NameKeyValue, WatchdogKeyValue); modtcpKeepalive(NameKeyValue, KeepAliveKeyValue); modtcpInit();

There are four types defined for the PLC controlled devices. Accessing these different device types is done from the ODB by modifying boolean and integer values.

The Controllable Device type is a valve, heater, or other device that is turned on and off. Before the device can be turned on, all interlocks in the PLC must be satisfied, so the status of the device must be examined before the device is controlled. The ODB schema for a Controllable Device is as follows:

Key name Type #Val Size Last Opn Mode Value

---------------------------------------------------------------------------

SV1 DIR

Type INT 1 4 4h 0 RWD 1

CommandRegister INT 1 4 4h 0 RWD 193

StatusRegister INT 1 4 4h 0 RWD 289

Command DIR

On BOOL 1 4 4h 1 RWD n

Off BOOL 1 4 4h 1 RWD n

Reset BOOL 1 4 4h 1 RWD n

Status DIR

On BOOL 1 4 4h 0 RWD n

Off BOOL 1 4 4h 0 RWD n

InterlockOK BOOL 1 4 4h 0 RWD n

InterlockBits BOOL 8 4 4h 0 RWD

[0] n

[1] n

[2] n

[3] n

[4] n

[5] n

[6] n

[7] n

BitNames STRING 8 32 4h 0 RWD

[0] TEC status + site air

[1] SV4 Closed

[2] CG1 >= max vac

[3] PD1 >= max1

[4] AV1 Open

[5]

[6]

[7]

For device control, an examination of the device status will indicate if interlocks are satisfied, and if not, which bits are indicating a problem. There is no information presented in the ODB to tell the operator what must be done to satisfy interlocks for a device. Once interlocks are satisfied, the Command/On value can be set to y which will send the command to the PLC. The driver will clear the bit after one second, and update the ODB to set the value back to n. Examining the Status/On value will indicate the state of the device.

The Value type is an analog signal from a sensor. The ODB schema for a Value is as follows:

Key name Type #Val Size Last Opn Mode Value

---------------------------------------------------------------------------

CG1 DIR

Type INT 1 4 4h 0 RWD 2

ValueRegister INT 1 4 4h 0 RWD 33

Measured FLOAT 1 4 4h 0 RWD 0

Slope FLOAT 1 4 4h 0 RWD 1

Offset FLOAT 1 4 4h 0 RWD 0

The Setpoint type is a floating point value that is used by a function in the PLC. The ODB schema for a Setpoint is as follows:

Key name Type #Val Size Last Opn Mode Value

---------------------------------------------------------------------------

Max1WindowSP DIR

Type INT 1 4 4h 0 RWD 3

SetRegister INT 1 4 4h 0 RWD 225

ReadRegister INT 1 4 4h 0 RWD 1001

Setpoint FLOAT 1 4 4h 1 RWD 0

Measured FLOAT 1 4 4h 0 RWD 0

Slope FLOAT 1 4 4h 0 RWD 1

Offset FLOAT 1 4 4h 0 RWD 0

The Digital Bits type is a word containing a variety of discrete bits indicating the state of various PLC devices. The ODB schema for a Setpoint is as follows:

Key name Type #Val Size Last Opn Mode Value

---------------------------------------------------------------------------

InputReg1 DIR

Type INT 1 4 4h 0 RWD 4

BitRegister INT 1 4 4h 0 RWD 19

Bits BOOL 16 4 4h 0 RWD

[0] n

[1] n

[2] n

[3] n

[4] n

[5] n

[6] n

[7] n

[8] n

[9] n

[10] n

[11] n

[12] n

[13] n

[14] n

[15] n

BitNames STRING 16 32 4h 0 RWD

[0] SV3_Int_Over_RS

[1] TEC_Out_Mode_RS

[2] PV_Mode_RS

[3] Normal_Mode_RS

[4] Clear_Fault_RS

[5]

[6] Site_Air_LS

[7] HVPS2_off_LS

[8] HVPS1_off_LS

[9] CG2_Low_LS

[10] CG2_High_LS

[11] CG1_Low_LS

[12] CG1_High_LS

[13] GV1_Closed_LS

[14] GV1_Open_LS

[15] Tec_in_RS

1.2.18

1.2.18